Ukuthiingilazi rovings or imicu yengilazi emifushane, i-fiberglass ephezulu or I-precio fibra de carbonozengezwa ku-matrix ye-thermoplastic, inhloso ngokuyisisekelo ukuthuthukisa izakhiwo zemishini nesakhiwo se-polymer.Kunomehluko omningi phakathi kwezindlela ezimbili eziyinhloko zokuqinisa i-thermoplastics yokubumba umjovo, kusukela ekuhlanganisweni kwe-polymer matrix, kuya ezingeni lokusebenza abangakunikeza, futhi ifomu elilodwa le-fiber lingase libe ngaphezulu Enye ifaneleka kakhulu, kodwa i-shapper, umehluko omkhulu phakathi kwemicu emifushane nemide yizinga ecutshungulwa ngalo.

Ukucubungula i-fiber ende eqiniswe yi-thermoplastics

Umgomo oyinhloko wokucubungula i-thermoplastics eqiniswe ngefayibha ende ukugcina ubude befayibha, okubalulekile ekuthuthukiseni amandla nokuqina.Ukuphuka kwefiber kungaba nomthelela ongemuhle ezimpahleni zenhlanganisela ye-polymer futhi kungase kugcine kunganaki izinzuzo zokusebenzisa imicu yefiber yengilazi.Ukuphatha okungalungile kanye namathuluzi angalungile kanye nomklamo wengxenye, noma ukusetshenziswa kwemishini yokucubungula engalungiselelwe noma ukusetha, kungaholela ekwephukeni kwefayibha.

Ngokungafani namapulasitiki aqiniswe ngefayibha eqoshiwe, izinto eziqiniswe ngefiber ende ngokuvamile zenziwe nge-pultrusion.Inqubo ihilela ukwelulaingilazis ukuzulazulaifakwe inhlaka ye-thermoplastic ngokusebenzisa i-pregnation die ekhethekile (ukuze i-resin ikwazi ukugoqa futhi ibophe imicu), bese isika imicu ekhishwe ibe ngamapellets, imicu kuma-pellets ivamise ukuba ngu-12mm Izici ezinde, ezigcwele ubude obugcwele unidirectional fiber reinforcement. , futhi lobu bude bubalulekile ukuze i-polymer ikwazi ukudlulisa kahle ingcindezi emicu eqinile.

Uma la ma-pellets esetshenziselwa ukubumba umjovo, imicu emide iqondaniswe futhi iboshwe ngokuqinile ukuze yakhe uhlaka lwamathambo lwangaphakathi olunikeza amandla nokuqina.Uma kuqhathaniswa nezinto ezigcwele i-fiber emifushane, izinhlanganisela eziqiniswe ngemicu emide, noma ngabeimicu ye-fiberglassnoma ama-carbon fibers, ahlinzeka ngezilinganiso eziphakeme zamandla nesisindo, ukuqina komthelela, impilo ende yokukhathala okujikelezayo, kanye nokumelana nokushisa okubanzi nokuzinza okungcono kobukhulu.

Lezi zinto ezihlala isikhathi eside zinikeza ukusebenza kwesakhiwo okuqhathaniswa nensimbi, nokho zilula kunensimbi, futhi ziyakwazi ukusizakala ngezinzuzo zokucubungula kahle zokubumba umjovo.1k indwangu ye-carbon fiberibaluleke kakhulu esikhundleni sensimbi ngoba ilula ngo-70% kunensimbi futhi ilula kunensimbi.I-Aluminium ilula ngo-40%, ngakho-ke izinhlanganisela eziqiniswe isikhathi eside zingasetshenziswa ukwenza izingxenye ezidingekayo ezimotweni, ezimpahleni zemidlalo, emkhathini, ezimpahleni zabathengi nasezimbonini.Izinsalela eziyisisekelo ezijwayelekile zihlanganisa i-polyamide (PA noma inayiloni), i-polypropylene (PP), i-thermoplastic polyurethane eqinile (ETPU), kanye nezinsalela zokushisa eziphakeme njenge-polyetheretherketone (PEEK), i-polyphthalamide (PPA), ne-polyamide.I-Ether imide (PEI) njll. Nakuba noma iyiphi i-thermoplastic ingaqiniswa ngemicu, eminye kuphela enikeza ukusebenza okuphezulu ngoba iqiniswe kangcono.Ngokuqondile, ama-semi-crystalline resins aqiniswa kangcono yi-fibers kune-amorphous resins, okusho ukuthi ukuqina nokuqina kwawo kwanda nakakhulu.

Amaphuzu Okucubungula Wezinto Eziqinisiwe Ze-Fibre ende

Uma kuqhathaniswa nama-resin angalungisiwe noma agcwele impushana egcwele impushana, ukubumba izinhlanganisela eziqiniswe ngefayibha ende kunezidingo ezithile ekubunjweni, emasangweni, okokusebenza kokubumba, kanye nokwakhiwa kwengxenye.Izinqubo ezisetshenziselwa ukucubungula lezi zinto nazo zihlukile kulezo zama-polymers aqiniswe nge-fiber emfushane.

Njengoba kushiwo ngaphambili, ukugcina ubude be-fiber kuyisihluthulelo sempumelelo.Izinto ezingabangela ukufinyezwa kobude befayibha zifaka ukucindezela okuphezulu nokushear kusukela kusikulufa somjovo, njengamakhona acijile kusistimu yokubunjwa neyomgijimi.Ukugcina ubude be-fiber, kunamaphuzu amathathu okucubungula abalulekile okufanele uwaqaphele:

1. Isikhunta kanye nomklamo

Nakuba imicu emide igqoka kancane esikhunjeni kunemicu emifushane ngoba kuneziphetho ezimbalwa ezifana nenaliti ezifana ne-fiber ezithinta isikhunta, uhlobo olufanayo lwensimbi yokubumba lufaneleka kokubili ama-polymers aqiniswe nge-fiber ende kanye ne-fiber-fiber, evamile kakhulu Eyokuqala. iyinsimbi yokubumba engu-P20, engamelana nemijovo engaphezu kuka-100,000 ngokuqhubekayo.Uma kudingeka ukuqina okuphezulu (imijikelezo yomjovo engaphezu kuka-100,000), insimbi ye-H13 chrome molybdenum noma insimbi eqinile engu-A9 yizinqumo ezingcono.Ngokuvamile, isikhunta esiqinile siyisinqumo esingcono kakhulu sokucubungula i-thermoplastics eqiniswe nge-fiber.Ezikhunjini ezigugile, zingavuselelwa kusetshenziswa ubuchwepheshe be-electroplating.Ukubunjwa kwe-aluminium kungasetshenziswa ngisho uma kufanele kukhiqizwe ama-prototypes ukuze kuqinisekiswe umklamo.

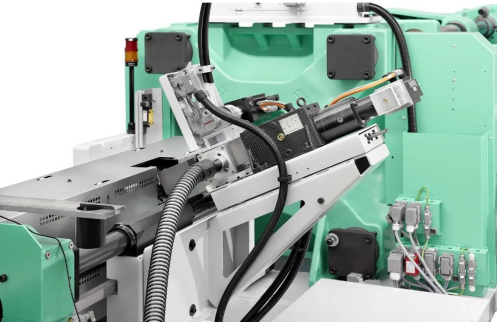

2. Imishini yokwakha

I-thermoplastics eqiniswe ngefayibha ende ingacutshungulwa kusetshenziswa okokusebenza okujwayelekile komjovo okunezinguqulo ezimbalwa kuphela ezingahlali unomphela ukuze kulondolozwe ubude befayibha kanye nokufaka ama-viscosity aphezulu.Ingcindezi ephansi noma isikulufu senhloso evamile esinendandatho engabuyi evumela ukugeleza kwamahhala phezulu kuyanconywa.Imibhobho yenhloso evamile ingasetshenziswa, kodwa imilomo yenayiloni kufanele igwenywe ngoba umumo wayo we-hourglass (eklanyelwe ukuvimbela ukuconsa) uvimbela ukugeleza, udale ukugunda, futhi ubangele ukuhuzuka kwemicu.Elinye ithiphu lokunciphisa ukugunda ukugwema imiklamo ye-cone nozzle ehlanekezelwe.Ngokuvamile, izimbobo zenozzle ezinkulu (ubuncane obungu-5.6 mm) zisiza ukudlula kwama-resin aqiniswe nge-viscous fiber.

Umthetho omuhle wesithupha wanoma yimuphi umshini womjovo uwukujova kuphela u-60-70% wevolumu.Usayizi wokudutshulwa omningi unyusa isikhathi sokusetha kabusha, kuyilapho usayizi wokudutshulwa omncane kakhulu usho ukuthi okubalulekile kuhlala emgqonyeni isikhathi eside, okungase kuholele ekulimaleni.

3. Izimo zokucubungula

Mayelana nokucubungula, kubalulekile ukubhekana nezindaba ezimbili: i-warpage kanye ne-creep.Ngokuvamile, izingxenye ze-thermoplastic eziqiniswe ngefayibha ende zine-warpage encane kunaleyoingilazi ye-fiberglass emfushaneizingxenye ngenxa yokuthi ukusongwa komcu kunciphisa ukushwabana okuhlukile, kodwa izingxenye zefayibha ezinde ezibunjwe ngomjovo zisawohloka, esinye isizathu siwukuthi imicu igeleza ngokuhambisana nokuma kwe-Orientation, kuyilapho ithuthukisa ingxenye yamandla, ingaholela ku-anisotropy.Ukuze uvimbele ukungqubuzana, ezinye izindawo zesango noma izingxenye zemiklamo zingasetshenziswa ukuze kugwenywe ukulungiswa kwefayibha ngokweqile ezindaweni ezingadingi amandla aphezulu ukumelana nemithwalo yesakhiwo.

Gcina inzuzo yemicu emide

Ukubumba okuphumelelayo kwezinhlanganisela eziqiniswe ngefayibha ende kudinga ukuguqulwa okuthile kwemihlahlandlela yokuklama kanye nemingcele yokucubungula esebenza ku-resin engaqinisiwe nezinhlanganisela zefiber emifushane.Ukuze uthole okuningi kokuqiniswa kwefayibha ende (ebiza ngaphezu kwezinto ezingagcwalisiwe nomafiberglass oqoshiwe imicu ukuqinisangenxa yokusebenza kwawo okuphezulu), izindlela ezingcono kakhulu kufanele zilandelwe kuyo yonke inqubo.Uma amafayibha amade ephukile noma angahambi kahle ngenxa yokuphatha okungalungile, idizayini yokufa noma ukusethwa kwemishini, izinzuzo zayo zamandla aphezulu kanye nokuqina okuphezulu zizoncipha noma zilahleke.

#ingilazi rovings#imicu yengilazi emifushane#1k indwangu ye-carbon fiber#ingilazi ye-fiberglass emfushane#fiberglass oqoshiwe imicu ukuqinisa

Isikhathi sokuthumela: Oct-21-2022